Welcome to our latest review, where we delve into the world of precision machining with the 110V Pneumatic Punch Press Machine. After putting this powerhouse through its paces, we’re excited to share our insights on this desktop marvel, ideal for a myriad of applications, from electronics to jewelry and beyond. We all know that efficiency and safety are of utmost importance in any workspace, and this machine is engineered to prioritize both, marrying robust performance with essential safety features.

In our exploration, we’ve marveled at the thoughtful design elements, including the dual-hand control system that not only enhances user safety but also streamlines operation. With a sturdy build of 440 lbs and a pressure rating of 200 kg, it’s designed for serious tasks while maintaining a compact footprint. Whether you’re a small business owner looking to enhance your production capabilities or a hobbyist aiming to elevate your crafting game, understanding how this machine performs in real-world situations will be vital.

Join us as we uncover the capabilities, versatility, and practicality of the 110V Pneumatic Punch Press Machine, and see if it truly lives up to the promises made in its specifications. Through our firsthand experience, we aim to provide you with an honest assessment to help you make informed decisions about integrating this machine into your workflow. Let’s dive in!

Overview of the 110V Pneumatic Punch Press Machine Experience

Overview of the 110V Pneumatic Punch Press Machine Experience

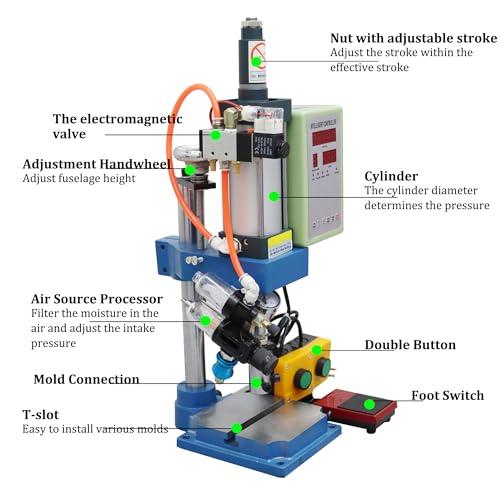

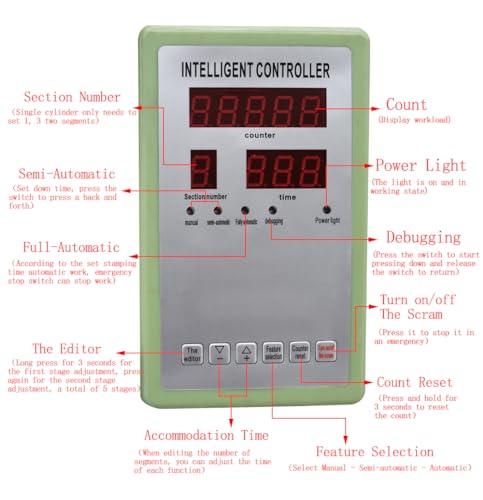

Our experience with this machine has been quite positive. The 110V setup ensures that it fits easily into our workspace without needing special electrical modifications. The pneumatic operation provides a powerful 440 lb/200 kg pressure, making it suitable for a variety of materials including electronics, jewelry, and hardware. We appreciate the innovative design that allows for two-handed operation via manual switches or a footswitch, emphasizing safety during use by adhering to essential safety standards. The inclusion of features such as an air source processor and adjustable oil settings significantly enhances operational efficiency and user experience.

Another notable aspect is the machine’s versatility and ease of adjustment. The compact dimensions of 5.9 x 5.9 x 5.5 inches allow it to fit on any desktop, while the adjustable cylinder size meets a range of requirements for various projects. We found that adjusting the air pressure to our needs was straightforward, enabling us to achieve desired performance quickly. The lack of noise during operation further adds to its value, creating a more comfortable working environment. For those looking to boost their productivity with a high-performance punch press, this machine offers an excellent combination of robustness and user-friendly features.

| Feature | Details |

|---|---|

| Pressure | 440 lb / 200 kg |

| Working Countertop Size | 5.9 x 5.9 inches |

| Die Hole Diameter | 0.6 inches |

| Working Height | 5.5 inches |

Key Features That Elevate Our Craftsmanship

Key Features That Elevate Our Craftsmanship

Our machine stands out due to its robust safety features designed to enhance user protection. Utilizing a two-button manual control system ensures that both hands must be engaged to start operations, significantly reducing the risk of accidental activation. Furthermore, we have incorporated multiple safety mechanisms, such as advanced pressure sensors and temperature controls, which adhere to recognized safety standards. These enhancements not only safeguard the operator but also maintain the integrity of the machine during demanding tasks.

In addition to its safety, our equipment is built for efficiency and ease of use. It features a straightforward air pressure adjustment system that allows users to set their desired output efficiently, ensuring precise performance tailored to various applications. The compact design coupled with a high operational capacity (440 lb/200 kg of pressure) makes it an ideal choice for a wide range of industries, from electronics to jewelry. Its versatility is further amplified by the ability to adapt to different cylinder sizes and configurations, elevating our commitment to quality craftsmanship and customer satisfaction.

| Feature | Description |

|---|---|

| Safety Controls | Dual manual switches for extra safety |

| Pressure Range | Adjustable from 0.7 to 0.8 MPa |

| Power Efficiency | Quiet operation with low power consumption |

| Versatility | Compatible with various cylinder sizes |

In-Depth Insights into Performance and Usability

In-Depth Insights into Performance and Usability

We were impressed by the seamless performance of this pneumatic punch press. The machine operates at a reliable 440 lbs of pressure, providing strong and consistent results across various applications. The adjustable air pressure allows for customization based on our specific needs, which enhances its versatility. The working height of 5.5 inches and a countertop size of 5.9 x 5.9 inches mean that this tool fits comfortably on most workstations while maintaining an efficient workspace. Additionally, the ease of operating the manual switches, requiring both hands for safety, reassures us about its compliance with safety standards, adding an extra layer of protection during usage.

Usability has been designed with user-friendliness in mind. The setup process is straightforward, and clear instructions guide us in adjusting settings such as height, stroke, and speed according to the task at hand. The incorporation of features like anti-rotation guide rods further enhances precision, reducing the risk of misalignment during operation. Furthermore, the lack of noise from the hydraulic system during use keeps the workspace pleasant. This machine proves to be advantageous for various projects, including electronic and electrical components, jewelry, and garments, making it a valuable tool in our workshop arsenal.

Recommendations for Optimal Use and Maintenance

To ensure the best performance of our pneumatic punch press, we should follow established operating protocols. Always use both hands on the control button or foot switch to maintain safety and to comply with operational standards. It is important to regularly check the air source processor. We can turn off the air supply with the blue switch, drain any accumulated water by lifting the copper nozzle, and maintain proper oil levels by adjusting the cap and oil cup as needed. Regularly inspect and clean the interior components to prevent debris build-up, which could hinder performance.

When it comes to maintenance, adhering to a schedule is crucial. We recommend the following steps to prolong the life of the machine:

| Maintenance Task | Frequency |

|---|---|

| Check air pressure settings | Weekly |

| Inspect and refill oil | Monthly |

| Clean the punch mechanism | As Needed |

| Check safety features | Monthly |

By systematically following these practices, we can minimize downtime and ensure consistent operation. If we feel ready to take our projects to the next level, let’s explore further options available on Amazon.

Pros & Cons

Pros & Cons of the 110V Pneumatic Punch Press Machine

As we delve into the features of the 110V Pneumatic Punch Press Machine, it’s important to weigh the advantages and disadvantages to help us make an informed decision. Here’s a balanced look at what this machine has to offer:

| Pros | Cons |

|---|---|

| ⭐ User-Friendly: Its simple structure and easy-to-operate design make it accessible for both beginners and experienced users. | ⚠️ Noise-Free Operation: While it’s marketed as quiet during hydraulic operations, some users might find slight air compressor sounds disruptive in quiet environments. |

| ⭐ Safety Features: The requirement to use both hands to operate the machine enhances safety and minimizes the risk of accidents. | ⚠️ Limited Size: The working countertops size of 5.9 x 5.9 inches may not be sufficient for larger projects. |

| ⭐ Versatile Applications: Suitable for a wide range of industries including electronics, jewelry, and garment, making it a versatile tool for multiple projects. | ⚠️ Pressure Adjustments: The air source pressure settings may require experimentation to find the optimal levels for different materials, which could be time-consuming. |

| ⭐ Cost-effective: It offers superior performance at a relatively low price, which can help reduce overall production costs. | ⚠️ Dependency on Air Supply: It necessitates an air compressor, which might add to the initial setup cost and complexity. |

| ⭐ High Precision: Features like anti-rotation guide rods and customizable settings allow for precision work and adjustable outcomes. | ⚠️ Footswitch Usage: While the footswitch adds convenience, it requires additional focus, which might be challenging in fast-paced work environments. |

We find that the 110V Pneumatic Punch Press Machine combines functionality with safety and versatility. However, we should also consider the limitations and prepare accordingly. Ultimately, its place in our toolkit will depend on specific project needs and preferences.

Q&A

Q&A Section: Exploring the Features of the 110V Pneumatic Punch Press Machine

Q1: What makes the 110V Pneumatic Punch Press Machine suitable for various applications?

A: We believe the versatility of this punch press is one of its strongest features. It is designed to handle a range of materials including those used in electronics, electrical appliances, instruments, meters, cameras, jewelry, and even garment manufacturing. With its capability to accommodate different cylinder sizes and the maximum punch depth of 28 mm, it meets the diverse needs of various industries.

Q2: How does the safety feature work with the manual controls?

A: Safety is paramount for us when operating machinery, and this punch press doesn’t disappoint. To start the machine, both hands must be used to press two manual switches simultaneously. This two-handed operation minimizes the risk of accidental startups. Additionally, the option to use a foot switch adds another layer of safety, allowing us to maintain a safer working environment.

Q3: Can we adjust the pressure settings easily? How does that affect our operations?

A: Yes, we can easily adjust the air pressure between 0.7 to 0.8 MPa. This adjustability allows us to tailor the machine’s performance to our specific needs, enhancing efficiency and precision. Moreover, the ability to set the pressure according to the material being processed can help us achieve high yield and optimal results.

Q4: What is the significance of the machine’s power consumption features?

A: The punch press is designed with power-saving features, which is crucial for reducing operational costs. Its simple structure minimizes energy use, and the hydraulic system operates quietly, which further aids in energy conservation. The air compressor operates efficiently, starting at 6kg and stopping at 8kg, ensuring that we can maintain peak performance without excessive energy expenditure.

Q5: Is it difficult to operate the 110V Pneumatic Punch Press Machine?

A: Not at all! We find this machine user-friendly, even for those who may be new to using pneumatic presses. The operational setup is straightforward, and the adjustments for height, stroke, and pressure are intuitive. Equipped with anti-rotation guide rods and a guide plate, it enables high-speed precision punch overload management, enhancing user experience and control.

Q6: What are the machine’s dimensions, and does that affect its usability?

A: The compact dimensions (5.9 x 5.9 x 5.5 inches) and a weight of 36.46 pounds make this machine suitable for desktop use, which is convenient for users like us with limited workspace. Despite its smaller footprint, it does not compromise on power or capability, making it accessible for both hobbyists and professionals.

Q7: Are there any maintenance requirements we need to be aware of?

A: Maintenance is fairly simple for this press. The air source processor requires us to regularly drain water from the copper nozzle and adjust the oil absorption as needed. Additionally, the oil cup can be removed for refueling, which facilitates easy maintenance and ensures the press operates smoothly.

Q8: How does this machine compare to other punch presses on the market?

A: From our perspective, the 110V Pneumatic Punch Press Machine stands out due to its combination of safety features, ease of use, and versatility. While many punch presses offer brute force, this model excels in precision and control, making it an ideal choice for intricate applications. Moreover, its cost-effectiveness sets it apart, as it delivers superior performance without excessive power consumption.

Feel free to reach out if you have any more questions about the 110V Pneumatic Punch Press Machine as we explore its features together!

Discover the Power

As we wrap up our exploration of the 110V Pneumatic Punch Press Machine, it’s clear that this tool packs a punch—figuratively and literally! With its robust design, user-friendly features, and enhanced safety mechanisms, this machine offers an excellent solution for a variety of applications, from electronics to jewelry making. We appreciate how easy it is to adjust and customize according to our specific needs, making it a versatilе addition to any workshop.

Whether you’re a seasoned fabricator or a DIY enthusiast, investing in machinery that balances superior performance with safety is essential, and we believe this punch press checks all the boxes. We hope this review has illuminated the incredible potential this machine holds for enhancing your crafting and production endeavors.

If you’re ready to take your projects to the next level, why not consider adding this pneumatic punch press to your toolkit? For more details or to make a purchase, click the link below:

Discover the 110V Pneumatic Punch Press Machine today!

Thank you for joining us on this journey of discovery. Happy crafting!

Reviews

There are no reviews yet.